The

MRH

service procedure

|

DEBONDING

The debonding of old gaskets using a specially controlled oven ensures against any structural damage that can occur using other methods. MRH’s oven raises the temperature steadily until it reaches 200°C when the adhesive becomes tacky allowing the gasket to be easily removed. This facility means that as many as 250 plates can be debonded at one time reducing the time taken dramatically.

|

|

CHEMICAL CLEANING

A series of chemical tanks are used to clean 250 plates at a time. A Sulphamic acid is used for the removal of rust, steam deposits and organic products. A hot caustic bath, heated to 90°C is used to remove fatty acids, oils, non-organic matter and excess adhesive. Finally water wash is used to neutralise any chemical deposits remaining on the plates before they are sprayed with a high pressure hot water jet. |

|

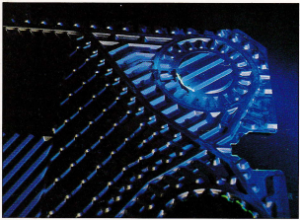

CRACK DETECTION

Crack detection is one of the highest priorities, MRH use a dye penetration method which is used in a dark room under utra-violet light and gives the best possible indication of any cracks in the plate. Failed plates are scrapped and replaced with the manufacturers genuine parts. |

|

REGASKETING & OVEN CURING

MRH can supply genuine and non-genuine plates and gaskets, all fully guaranteed to our customers requirements, After being checked for alignment the plates, which can be up to 500 in number, are held in a jig and oven cured for three and a half hours at 15% above the maximum working temperature of the heat exchanger. After curing each plate is once again checked for alignment and to make sure there is no excess adhesive. |